What are the connection methods of PE water supply pipe

Jun 03,2020

As a widely used plastic pipe, PE water supply pipe has always been a favorite in the water supply pipe system, and its related knowledge has attracted much attention

As a widely used plastic pipe, PE water supply pipe has always been a favorite in the water supply pipe system, and its related knowledge has attracted much attention

1. Hot melt connection

Hot melt connection is a special heating tool to heat and melt the parts connected by PE pipes or pipe fittings under pressure. After the heating tool is taken out, pressure is applied to connect the two melting surfaces together, so that the two melting surfaces maintain a stable pressure for a period of time until the joint cools down. The hot-melt connection includes the hot-melt butt connection, the hot-melt socket connection and the hot-melt saddle connection.

2. Electrofusion connection

The electric fusion connection is to use a special embedded resistance wire of the electric fusion pipe fitting to closely connect the connection part of the charging PE pipe or pipe fitting, and the connection part of the PE pipe is heated and melted by the embedded resistance wire, and the connection part is connected into a whole until the joint cooling. Electrofusion connection can be used to connect polyethylene pipes or socket pipes of different types and different melt flows. Electric fusion connection is divided into electric fusion socket connection and electric fusion saddle connection.

3. Socket type flexible connection

The sleeve type flexible connection of polyethylene pipe is a new type of connection developed according to the sleeve type flexible connection principle of cast iron pipe and PVC pipe. One end of the polyethylene pipe is welded with a reinforced polyethylene socket. Socket type flexible connection is to directly insert one end of polyethylene pipe into socket connection of special pipe or pipe fitting, so as to realize PE pipe and pipe fitting according to and resist through lock ring socket and pressing, and seal rubber sealing ring.

4. Flange connection

Flange connection is mainly used for the connection of polyethylene pipes with metal pipes or valves, flow meters, pressure gauges and other supporting equipment. Flange connection mainly consists of polyethylene flange connection piece, steel or aluminum back pressure flange, steel or aluminum flange piece, gasket or sealing ring, bolt, nut, etc. Flange connection is to fasten bolts and nuts, so that the flange connection parts and flange parts are in close contact, so as to achieve the purpose of connection.

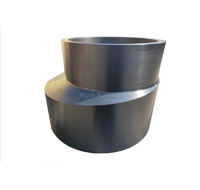

5. Steel plastic transition joint connection

Steel plastic transition joint is used to connect polyethylene pipe and metal pipe by cold pressing or other prefabricated steel plastic transition joint. Steel plastic transition joint has tensile lock ring and sealing ring, which usually requires the system to have better sealing performance, tensile strength and pressure resistance than polyethylene pipe. Commonly used PE water supply pipe connection mode generally has the above five kinds. We need to choose the appropriate connection mode according to different situations to achieve the effect of twice the result with half the effort.

PREVIOUS:

Contact Us

E-mail:

gjl@jydjsy.com

Mr.Gu (Tel):

86-18961696788 / 86-510-86378220

Tel:

86-510-86370651 / 86-510-86371315